P45 Multi-Purpose Applicator for Fertilizer, Granular Chemical and Seeds/Grains

Owatonna, MN, April 3, 2017: Gandy Company is pleased to offer the P45 Multi-Purpose 3-in-1 applicator for applying fertilizer, granular chemical, seeds and grain.

According to Randy Vargason, sales and marketing manager for Gandy Company, the 45 lb. capacity translucent poly hopper and matching lid allow the operator to easily gauge how much material is in the hopper and features a complete set of black metering wheels for granular chemical and small seeds, red metering wheels for fertilizer and small grains, plus, yellow high-output metering wheels for fertilizer. In addition a weather-tight lid with rubber latch straps keeps the elements out and the product secure.

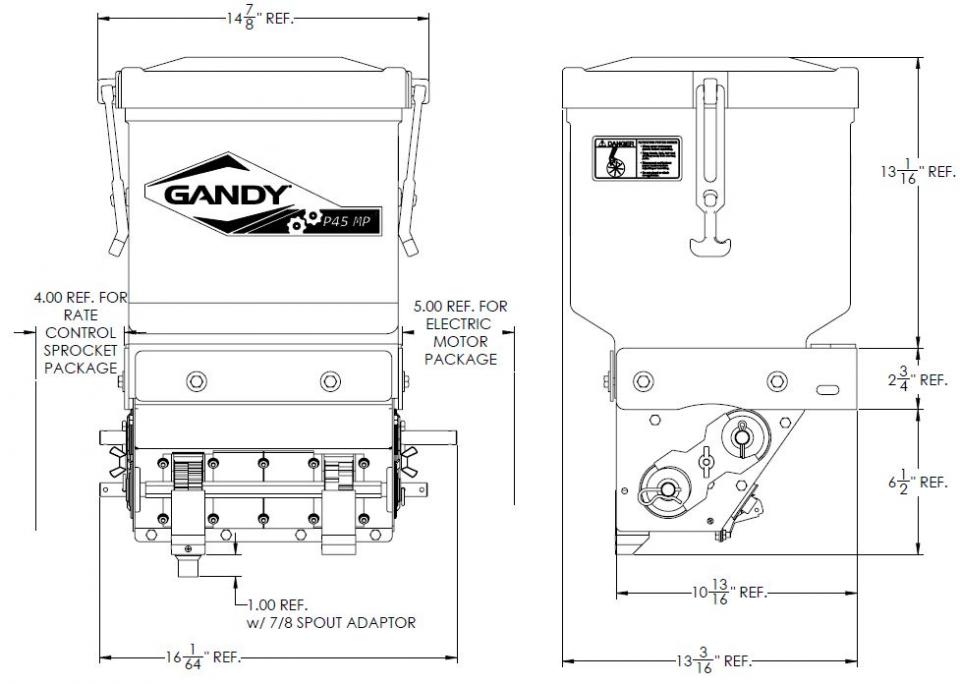

“Customers can easily configure the applicator from one to four outlets by simply sliding out the shaft and removing or installing metering wheels and cups. If not all outlets are used, blanking plates are provided to seal outlet openings. For surface mounting, each unit comes with a U-frame bracket with pre-drilled ½" holes and slots. An adjustable (14"-24") tool bar mount for a 5" diamond or 7" square tool bar is also available as an option.”

“Equipped with a stainless steel metering housing, a standard bolt-in agitator is included to assist in product flow. The positive displacement design means that when the metering stops, all flow stops. If the unit is ground-driven, the metering compensates for the ground speed. Other drive options include a standard 4-amp, 1/64 HP, 12-volt electric motor to drive up to two hoppers. If there are more than two hoppers mounted in-line, a heavy-duty, 25-amp, ¼ HP, 12-volt electric drive is available. Finally, a hydraulic drive option is available too. To achieve application rates, a rate control sprocket package is required and there are connector tubes to connect multiple hoppers together when they are mounted in-line. For customers that need to carry more material, a 30-lb. capacity hopper extension is available as an option.”

Gandy Company is an industry leader in the design and manufacture of agriculture application systems to farmers, ranchers, nurseries, universities, research firms and original equipment manufacturers to precisely apply seeds, grains, granular chemicals, fertilizers, inoculants and preservatives in an environmentally responsible manner. Gandy is also a trusted supplier of turf maintenance equipment to golf course superintendents, grounds maintenance professionals, facility managers, rental stores and OEM’s. The Company is headquartered in Owatonna, MN. The Gandy Company markets its products under the Gandy® brand name. Since 1936, Gandy has built its reputation on innovation, quality, customer service and integrity. More information is available on the Company web site at www.gandy.net.

SPECIFICATIONS:

- 45-lb. capacity (60-lb. per cu. ft. density) translucent poly hopper with UV and anti-static protection

- Translucent weather-tight cover with latch straps

- U-frame bracket with 1/2" pre-drilled holes and slots for surface mounting

- Stainless steel housing to resist corrosion

- Four each: Red (F) metering wheels; Black © metering wheels; Yellow (V) metering wheels

- Internal agitator

- Positive shutoff when metering stops

- Speed-compensated if ground-driven

- Fertilizer fed under metering wheel, then down tube

Drive Options

User will need to provide chain and drive sprocket to hopper input shaft from the parent implement's live shaft to provide 2 or 4 rpm to the Gandy input shaft depending on chemical rate, or purchase the Gandy ground drive package. If non-speed compensation is required, user may select a 12-volt drive.

Sprocket Package

Rate control sprocket package is required to set individual hopper rates and can control multiple hoppers when mounted in-line.

Connector Tubes

If multiple hoppers are mounted in-line, connector tubes will be needed to connect each hopper's drive and agitator shafts.

Tubing

Requires 1.5-inch I.D. tubing with hose clamps to secure tubing to outlets

Specifications are correct at the time of printing; however, Gandy Company reserve the right to change specifications, models, equipment or prices at any time without incurring obligation.

Randy Vargason

Sales & Marketing Mgr.

Ph. 800-443-2476

sales@gandy.net